DTG Printing Services Explained in Under 3 Minutes: Why Everyone Is Talking About Direct-to-Garment

- Janet Emma

- Oct 8

- 3 min read

What Is DTG Printing

DTG printing uses specialized inkjet technology to spray water-based inks directly onto fabric. The process creates high-quality, full-color designs without traditional printing limitations. The technology works like a desktop inkjet printer but targets textiles specifically.

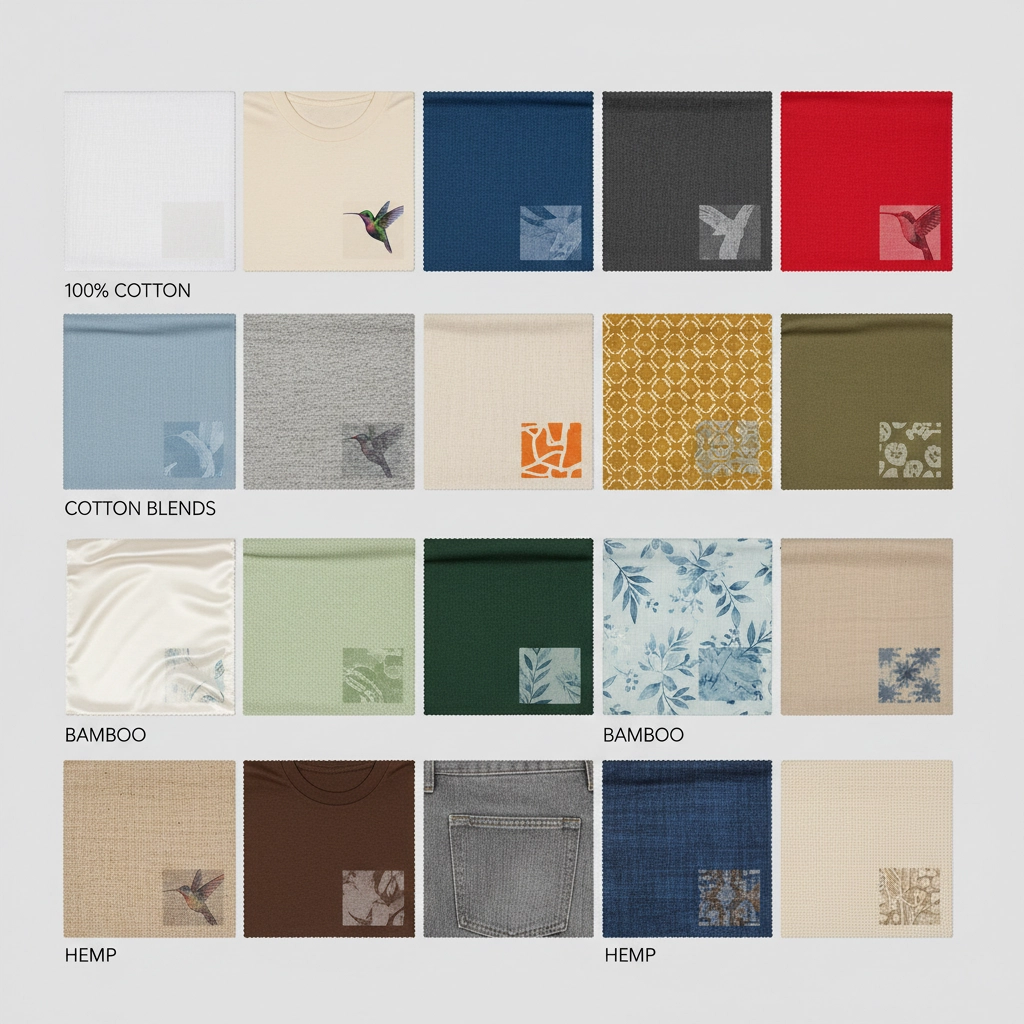

DTG printers handle natural fibers best: cotton, bamboo, hemp, linen. Synthetic materials require different approaches. The digital method eliminates screens, plates, and extensive setup procedures.

How DTG Works

Pre-treatment Stage

Apply bonding agent to fabric

Create stronger ink-fiber bond

Flatten loose fibers for smooth surface

Promote proper drying and curing

Essential for white ink on dark garments

Printing Process

Position garment on platen system

Apply white underbase (except white garments)

Print full-color design using CMYK inks

Maintain precise registration throughout

Curing Phase

Dry and set ink completely

Ensure wash resistance

Maintain color durability

Use conveyor dryer or heat press

DTG Advantages

No Minimum Orders DTG eliminates order minimums. Print single shirts profitably. No extensive setup required. No cleanup procedures between jobs.

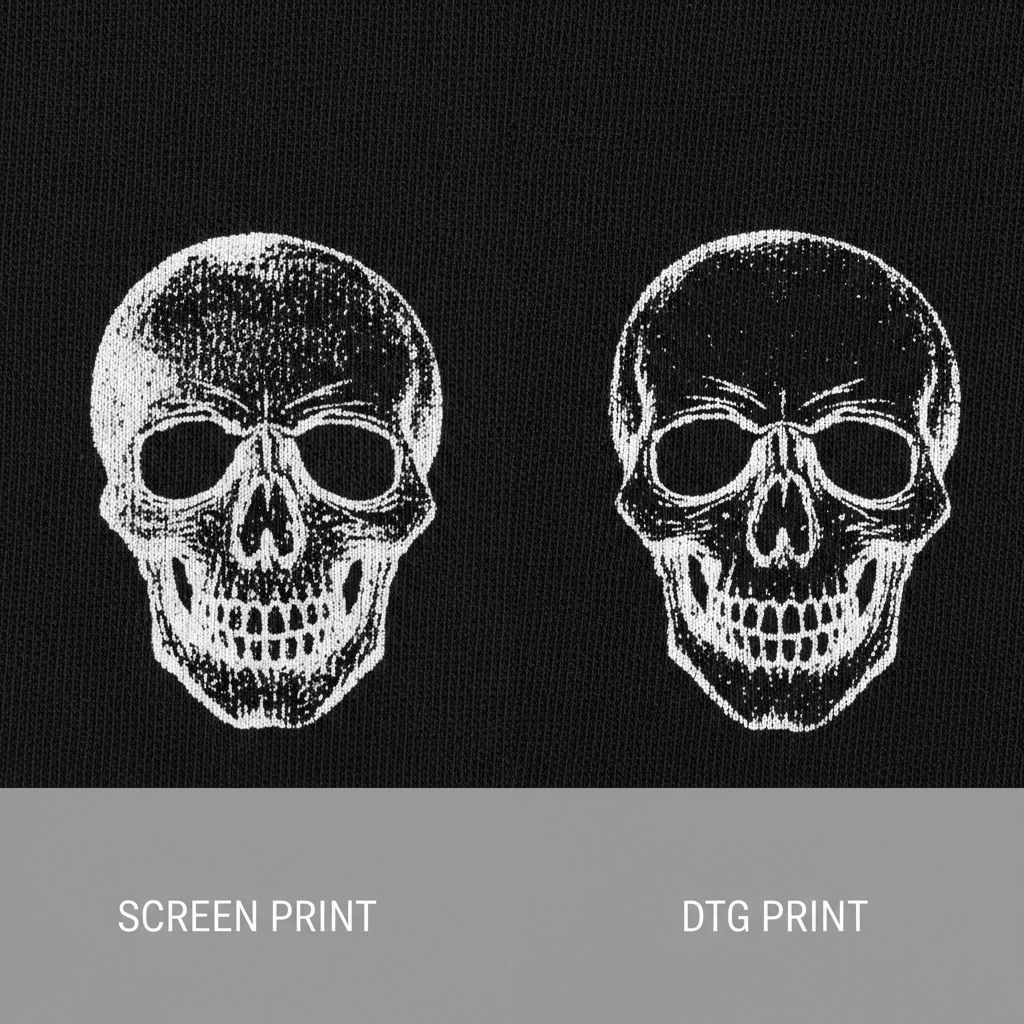

Superior Print Quality

Higher resolution than screen printing

Sharp detail reproduction

Full-color capability

Photographic quality possible

Consistent color matching

Fast Turnaround

Immediate printing capability

No screen preparation time

Quick job changeovers

Same-day completion possible

Cost-Effective for Small Runs Screen printing requires minimum quantities for profitability. DTG printing makes single items economically viable. Setup costs remain minimal regardless of quantity.

Why DTG Is Popular

Print-on-Demand Services DTG enables print-on-demand business models. Inventory requirements decrease significantly. Customer orders trigger production directly. Reduce waste and storage costs.

Personalization Market Custom apparel demand continues growing. Individual personalization becomes standard expectation. DTG meets personalization requirements efficiently.

Design Flexibility

Complex artwork handling

Multiple color capabilities

Photo reproduction quality

No color separation requirements

Digital file processing

DTG vs Traditional Methods

DTG vs Screen Printing Screen printing requires setup for each color. DTG handles multiple colors simultaneously. Screen printing suits large quantities. DTG works for any quantity.

DTG vs Heat Transfer Heat transfer creates thick feel on fabric. DTG inks absorb into fibers directly. Heat transfer may crack or peel. DTG provides permanent integration.

DTG vs Embroidery Embroidery adds texture and dimension. DTG maintains fabric hand-feel. Embroidery works for logos and text. DTG handles photographic images.

Best Fabrics for DTG

Cotton Products

100% cotton performs best

Consistent ink absorption

Excellent color vibrancy

Soft hand-feel maintained

Cotton Blends

50/50 cotton-polyester works well

Tri-blend options available

Performance may vary slightly

Pre-testing recommended

Specialty Fabrics Bamboo and hemp provide excellent results. Linen requires careful handling. Dark fabrics need white underbase. Light fabrics allow direct printing.

DTG Equipment Considerations

Printer Selection Epson F2000 series leads industry standards. Brother GTX models offer alternatives. Maintenance requirements vary by manufacturer. Support availability affects operations.

Pre-treatment Equipment Spray application systems work for small volumes. Dip tanks handle larger quantities. Automatic systems increase efficiency. Manual methods remain viable options.

Curing Solutions Conveyor dryers process high volumes efficiently. Heat presses work for smaller operations. Hybrid ovens combine both approaches. Temperature control remains critical.

Hard Re-Set Inc. DTG Expertise

Hard Re-Set Inc. operates professional DTG equipment for custom apparel production. Our services include:

Single piece orders accepted

Same-day turnaround available

Full-color design capabilities

Professional pre-treatment processes

Quality control procedures

Browse our custom printing services for immediate quotes and ordering.

DTG Market Applications

Artists and Designers Artists sell original designs on-demand. Designers test market reception without inventory risks. Creative professionals monetize artwork directly.

Corporate Customers Companies produce employee gifts and awards. Training programs create custom materials. Corporate events generate branded items.

E-commerce Operations Online stores offer unlimited design options. Print-on-demand eliminates inventory management. International shipping becomes feasible. Customer personalization scales efficiently.

Quality Control Factors

Ink Management

Regular maintenance schedules

Ink age monitoring

Color consistency checks

Nozzle cleaning procedures

Pre-treatment Quality Even application ensures consistent results. Coverage testing prevents print failures. Chemical mixing ratios affect performance. Environmental factors influence curing.

Curing Standards Temperature monitoring prevents under-curing. Time controls ensure complete ink setting. Wash testing verifies durability. Quality standards maintain reputation.

DTG Business Benefits

Low Entry Barriers DTG equipment costs less than traditional screen printing setups. Learning curves remain manageable. Initial inventory requirements stay minimal.

Scalability Options Start with single printer operations. Add equipment as demand grows. Expand service offerings gradually. Maintain operational flexibility.

Customer Satisfaction Quick turnarounds exceed expectations. Quality results generate repeat business. Personalization options create loyal customers.

Market Opportunities Custom apparel markets continue expanding. Print-on-demand services grow rapidly. Personalization trends drive demand.

Visit Hard Re-Set Inc. for professional DTG printing services. Our team handles projects of any size with guaranteed quality results.

Comments