How to Work with Motorcycle Clubs for Custom Printing: The Do's, Don'ts, and Secrets for Success

- Janet Emma

- Oct 22

- 5 min read

Working with motorcycle clubs requires understanding their culture, respecting their traditions, and delivering quality that matches their expectations. These groups value authenticity, brotherhood, and craftsmanship above all else.

Understanding Motorcycle Club Culture

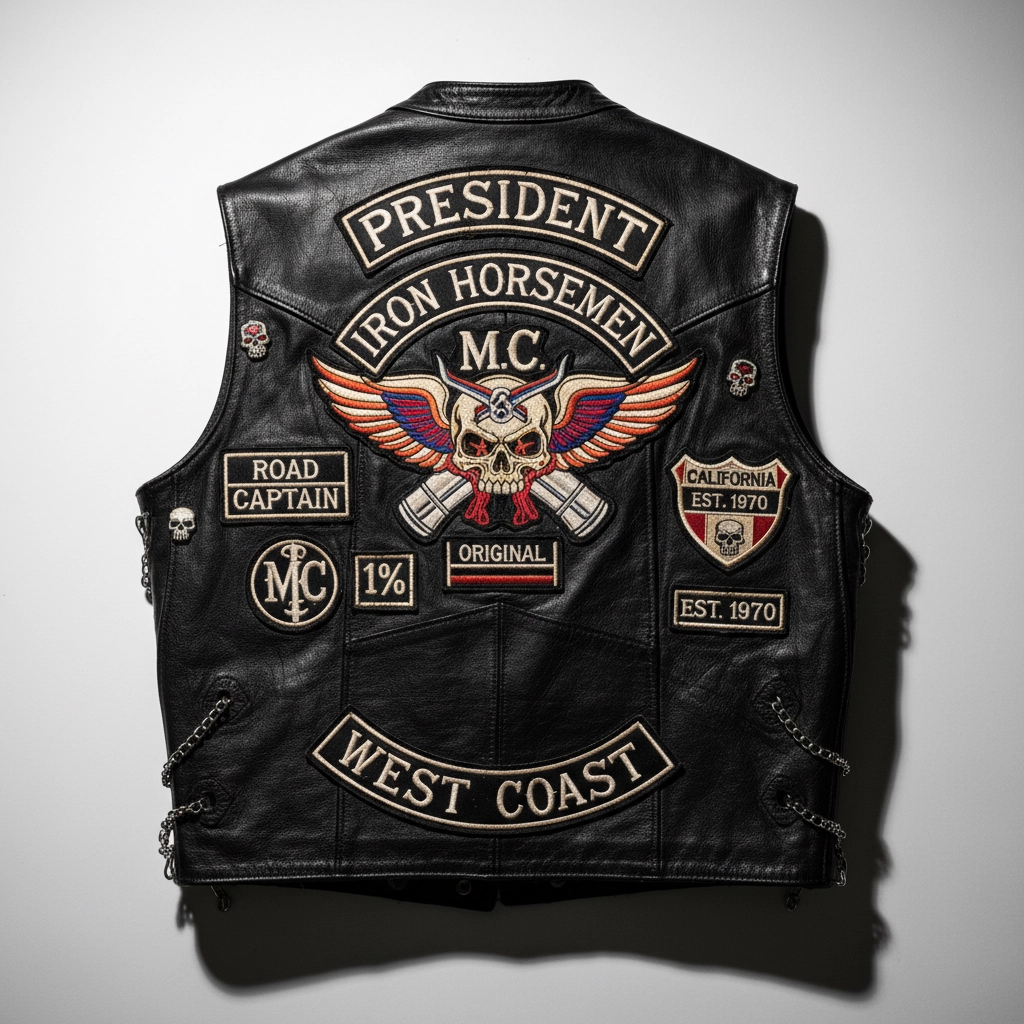

Motorcycle clubs operate with strict hierarchy and traditions. Custom apparel serves as identity markers, not just clothing. Each patch, logo, and design element carries meaning within the community.

Club merchandise builds unity and tells their story. Members wear custom gear with pride because it represents belonging and shared values. Respect this significance when approaching design and production.

Research the specific club before starting work. Learn their history, colors, and symbols. Ask about any design restrictions or requirements. This preparation shows professionalism and builds trust.

The Essential Do's

Build Authentic Relationships

Meet with club leadership face-to-face when possible. Attend events if invited. Show genuine interest in their riding culture and community values.

Listen to their vision before suggesting changes. Ask questions about design preferences, quality expectations, and timeline requirements. Document these conversations for reference.

Maintain regular communication throughout projects. Send progress updates, design mockups, and delivery schedules. Transparency prevents misunderstandings and builds confidence.

Prioritize Quality and Durability

Use premium materials that withstand motorcycle riding conditions. Fabrics must handle wind, weather, and frequent washing without fading or deteriorating.

DTF printing offers excellent durability for complex designs with multiple colors. Screen printing works well for simpler graphics with solid colors. Embroidery adds premium feel for patches and logos.

Test samples before full production runs. Check color accuracy, alignment, and adhesion quality. Replace any defective items without charging additional fees.

Respect Design Elements

Work within existing brand guidelines when customizing logos or patches. Maintain proper proportions, color schemes, and typography standards.

Understand which elements can be modified and which must remain unchanged. Some symbols hold sacred meaning within motorcycle culture and require exact reproduction.

Provide multiple design options when appropriate. Show different layout variations, color combinations, or effect applications. Let clients choose their preferred direction.

Critical Don'ts

Never Rush Quality

Avoid promising unrealistic deadlines that compromise craftsmanship. Motorcycle clubs prefer delayed delivery over substandard products.

Complex designs require proper setup time, color matching, and quality control checks. Grunge effects, gradient fills, and multi-location printing need careful attention to detail.

Build buffer time into project schedules for revisions, reprints, or unexpected complications. Communicate realistic timelines upfront to manage expectations.

Don't Ignore Club Hierarchy

Work through proper channels when receiving orders or making changes. Respect the chain of command within club structure.

Avoid casual familiarity with members until relationships develop naturally. Use formal communication initially, then adapt to their preferred style over time.

Never share one club's designs, contact information, or project details with competitors or other organizations. Maintain strict confidentiality about all client work.

Avoid Technical Shortcuts

Use high-resolution artwork files for all printing methods. Vector graphics work best for logos and text elements that require scaling.

Check file formats, color modes, and resolution requirements before starting production. Convert RGB designs to CMYK when necessary for accurate color reproduction.

Test different printing techniques on sample materials before committing to large orders. Document successful settings for future reference.

Secrets for Success

Master DTF Technology

DTF printing revolutionized custom motorcycle apparel production. This method handles complex designs with photographic quality, metallic effects, and fine detail reproduction.

Learn proper DTF setup procedures, temperature settings, and application techniques. Invest in quality equipment and materials for consistent results.

Practice grunge effects, transparency overlays, and multi-color registration before taking on challenging projects. Build expertise through experimentation and training.

Leverage Template Customization

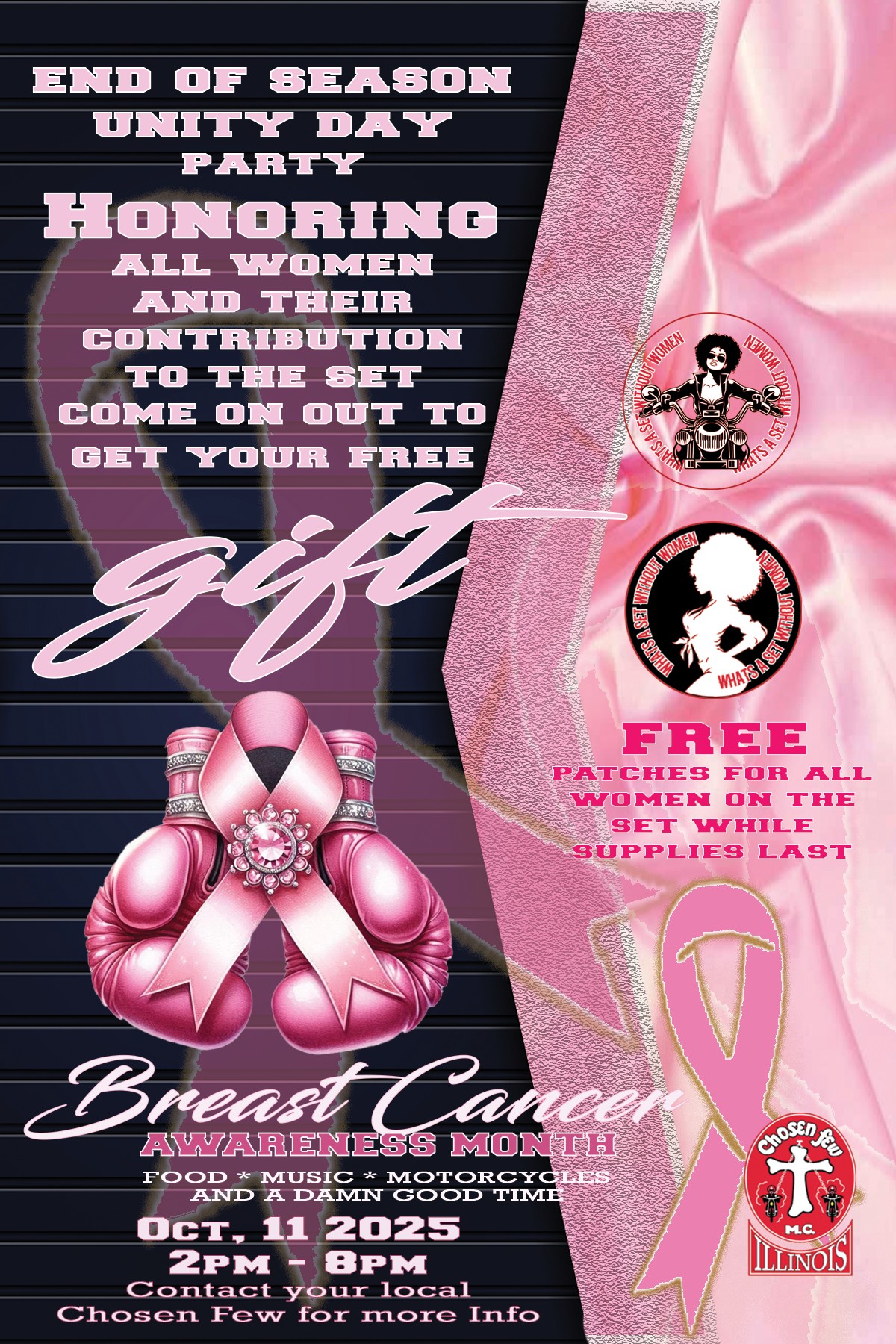

Start with proven motorcycle-themed templates, then modify typography, spacing, and effects for unique results. This approach balances efficiency with originality.

Customize color schemes to match club preferences while maintaining design integrity. Adjust text content, add club names, or incorporate specific imagery as requested.

Build a library of successful template variations for faster turnaround on similar projects. Document popular combinations and effect settings.

Create Exclusivity

Position custom merchandise as limited-edition items rather than mass-produced goods. This mindset elevates perceived value and justifies premium pricing.

Offer unique design elements that aren't available elsewhere. Develop signature effects, color combinations, or layout styles that become associated with your work.

Limit order quantities when appropriate to maintain exclusivity. Some clubs prefer smaller runs that ensure members have unique items.

Production Excellence

Multi-Product Capabilities

Expand beyond basic t-shirts to offer complete merchandise solutions. Jackets, vests, hats, patches, banners, and accessories create comprehensive brand packages.

Learn different decoration techniques for various products. Embroidery works well for caps and patches. Heat transfer suits performance fabrics. Screen printing handles large quantities efficiently.

Coordinate matching designs across multiple product types. Maintain consistent colors, fonts, and imagery throughout complete merchandise lines.

Quality Control Systems

Implement inspection procedures for every order. Check alignment, color accuracy, adhesion quality, and overall appearance before packaging.

Document common issues and their solutions. Train staff to recognize problems early in production processes.

Maintain replacement inventory for popular items. Quick response to quality issues builds customer loyalty and demonstrates commitment to excellence.

Safety and Compliance

Understand legal requirements for printing businesses. Maintain proper insurance coverage for equipment, liability, and business operations.

Follow safety protocols when operating printing equipment. Train staff on proper handling procedures for chemicals, heat presses, and machinery.

Keep detailed records of orders, artwork files, and customer communications. Protect client information and respect confidentiality agreements.

Building Long-Term Partnerships

Portfolio Development

Create case studies showcasing successful motorcycle club projects. Highlight design challenges, technical solutions, and client satisfaction results.

Photograph finished products professionally. Show items in use at events or worn by club members when permission allows.

Build specialized portfolio sections for different club types, design styles, and product categories. Demonstrate versatility within the motorcycle niche.

Word-of-Mouth Marketing

Exceed expectations on every project to generate positive referrals. Motorcycle communities share information about quality vendors through informal networks.

Attend motorcycle events and shows when possible. Build relationships within the community through genuine participation rather than aggressive sales tactics.

Offer referral incentives for existing clients who bring new business. Recognize loyal customers with special pricing or priority scheduling.

Technical Considerations

Equipment Investment

Invest in professional-grade equipment that handles motorcycle club design requirements. High-resolution printers, accurate color matching systems, and durable heat presses produce superior results.

Maintain equipment properly to ensure consistent quality. Schedule regular maintenance, replace worn parts, and upgrade technology as needed.

Train staff thoroughly on all equipment operation, safety procedures, and quality standards. Consistent training reduces errors and improves efficiency.

Workflow Optimization

Develop standardized procedures for order processing, design approval, production scheduling, and quality control. Consistent workflows reduce errors and improve turnaround times.

Use project management software to track orders, deadlines, and client communications. Automated reminders help prevent missed deliveries or forgotten follow-ups.

Maintain organized file systems for artwork storage, client information, and production records. Easy access to historical data supports repeat orders and troubleshooting.

Success in motorcycle club custom printing comes from understanding their culture, delivering exceptional quality, and building genuine relationships. Treat each club as a long-term partner rather than a single transaction. Consistency, respect, and craftsmanship create lasting business relationships within this tight-knit community.

Focus on becoming the trusted printing partner that clubs recommend to others. This reputation takes time to build but provides sustainable business growth through referrals and repeat orders. Quality work and professional service create the foundation for long-term success in this specialized market.

Comments